1. Introduction to PPR Pipes

1.1 What is PPR Pipe (Polypropylene Random Copolymer)?

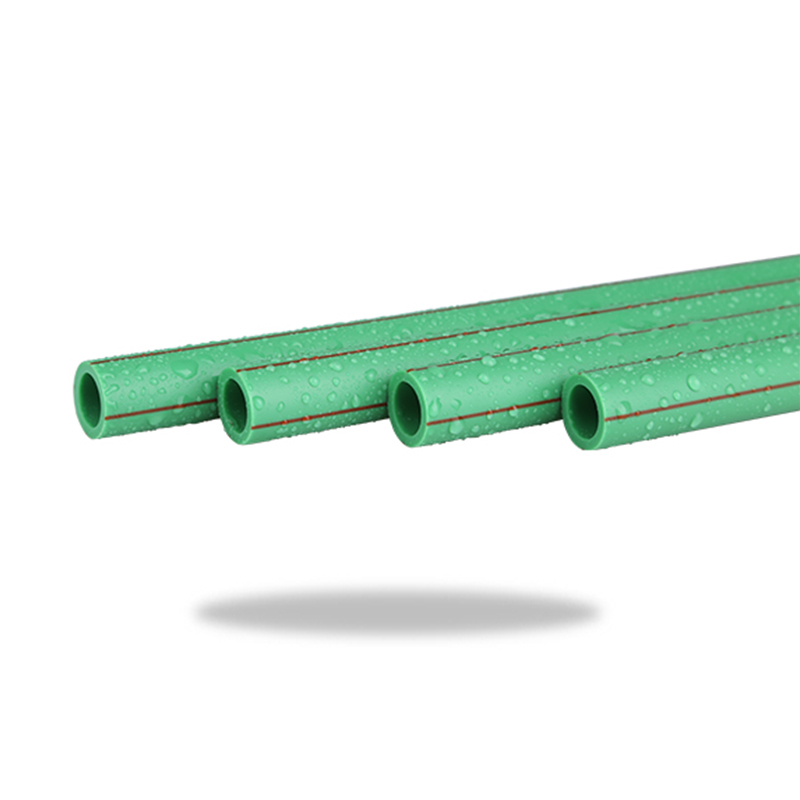

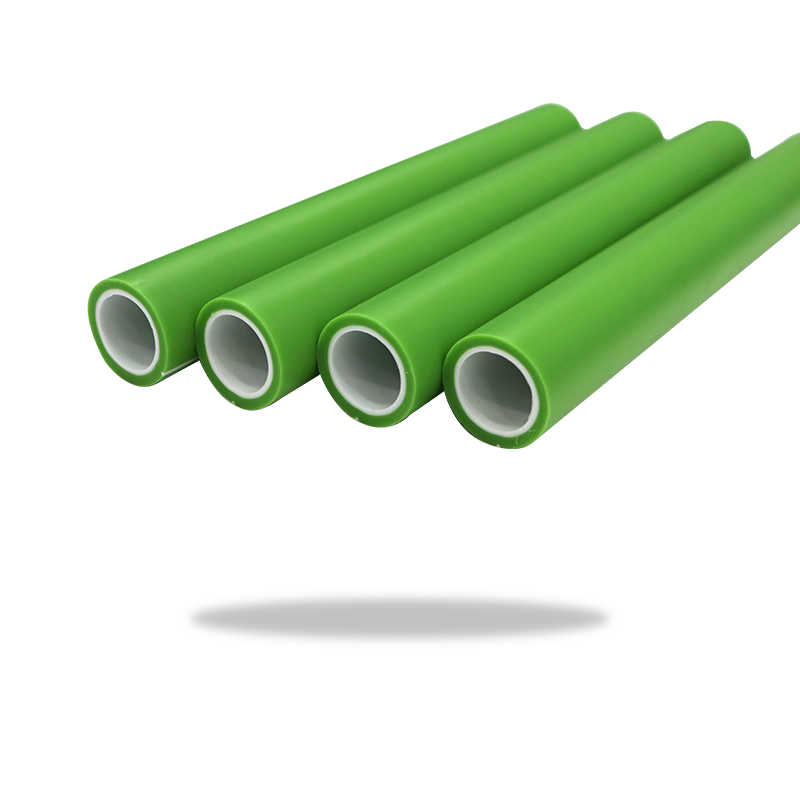

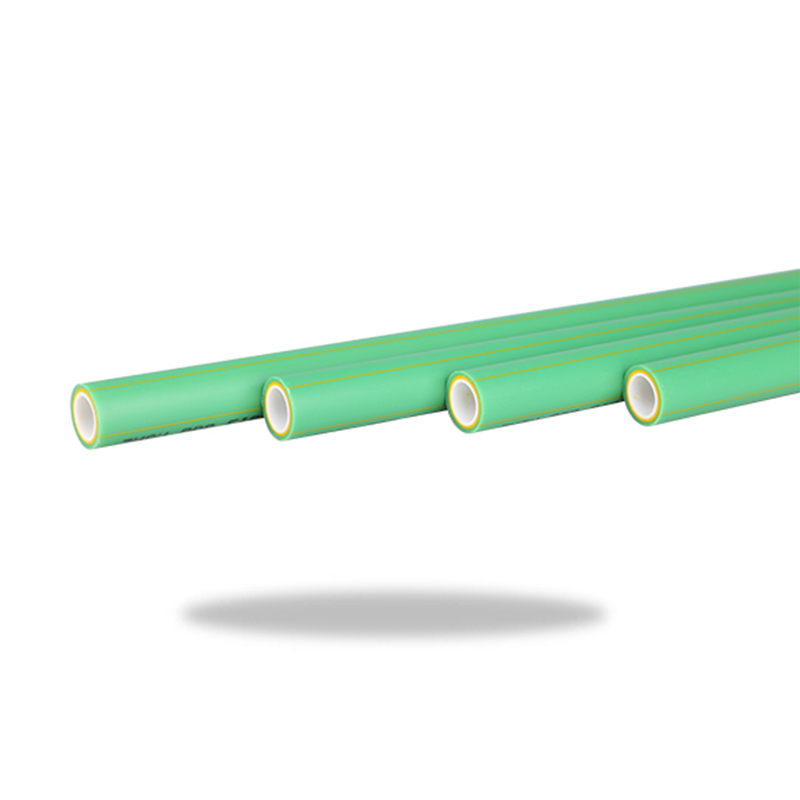

PPR pipe , short for Polypropylene Random Copolymer pipe, is a type of plastic piping system widely used in modern plumbing and mechanical installations. Made from a high-quality thermoplastic polymer, PPR is known for its excellent chemical and physical properties, particularly in handling both hot and cold water systems. Its smooth inner surface ensures low friction losses and resistance to scaling or corrosion, making it ideal for potable water distribution, heating systems, and industrial applications.

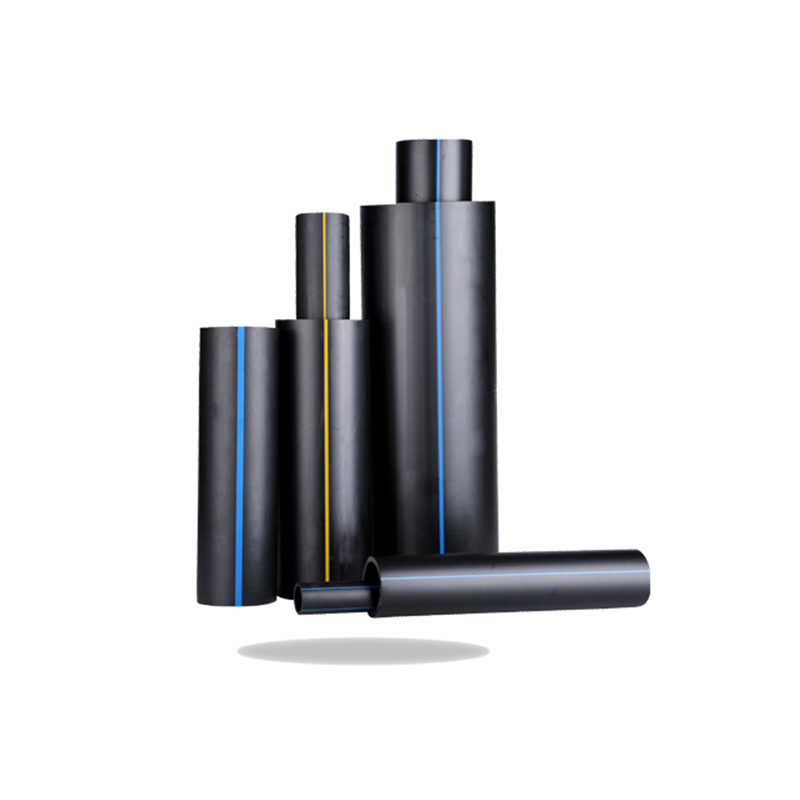

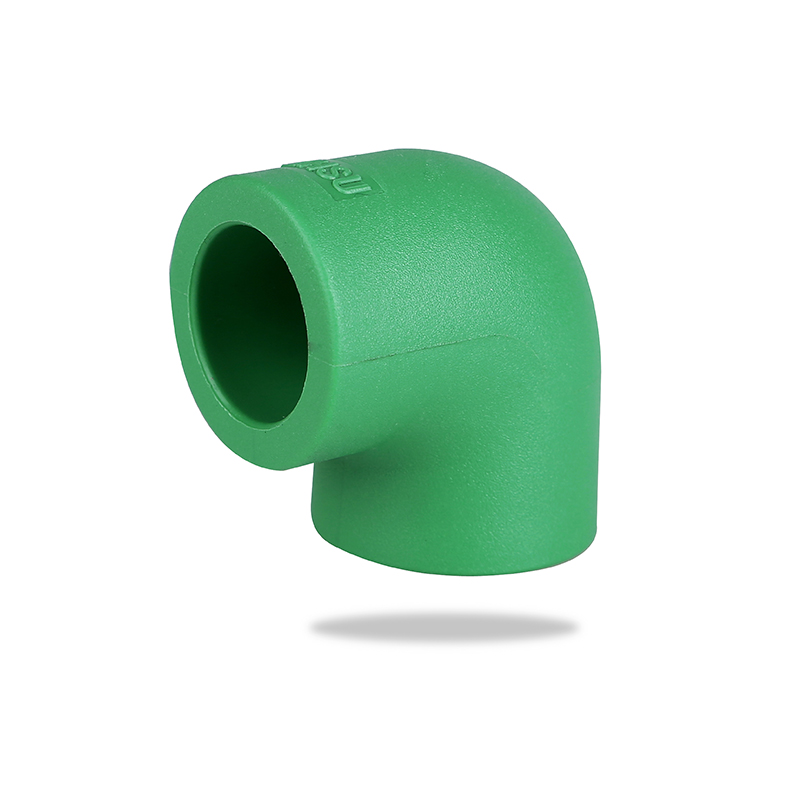

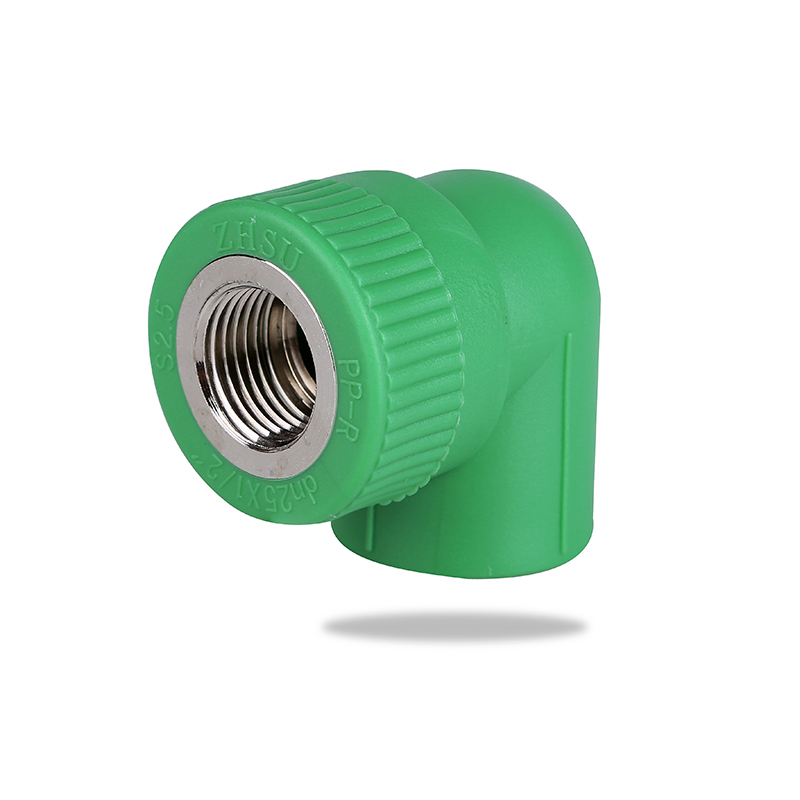

PPR pipes are typically available in green, white, or grey colors and come with a wide range of fittings, allowing for seamless integration and flexibility in design. They are joined using a heat fusion technique that creates a permanent bond between pipe and fitting, resulting in a leak-proof, homogenous system.

1.2 Brief History and Development

The development of PPR pipes dates back to the late 1980s and early 1990s when advancements in polymer chemistry led to the creation of random copolymers that combined flexibility and strength. The demand for non-corrosive, durable, and hygienic alternatives to metal pipes sparked interest in thermoplastic solutions. Over time, PPR emerged as a superior material, especially in Europe and Asia, where stringent water quality standards demanded better-performing piping systems.

As building technologies progressed and construction standards evolved, PPR pipes became an attractive choice due to their ease of installation, environmental friendliness, and long service life. Today, PPR pipes are recognized globally and used extensively in residential, commercial, and industrial infrastructure.

1.3 Why PPR Pipes are Gaining Popularity

Several factors contribute to the growing popularity of PPR pipes in the construction and plumbing industries:

Corrosion Resistance: Unlike metal pipes, PPR does not corrode or scale over time, maintaining consistent flow rates and water quality.

Durability: PPR pipes can last over 50 years under normal operating conditions, making them a cost-effective investment.

Safe for Drinking Water: The material is non-toxic and does not leach harmful substances, meeting international safety standards for potable water systems.

Thermal Resistance: They are suitable for both cold and hot water applications, withstanding temperatures up to 95°C in continuous use.

Ease of Installation: Lightweight and joined via heat fusion, PPR systems reduce labor costs and minimize leak risk.

Environmental Sustainability: Fully recyclable and energy-efficient to manufacture, PPR supports green building initiatives.

As green construction, sustainability, and efficiency become top priorities in global development, PPR pipes are increasingly favored for their long-term benefits and performance.

2. Properties of PPR Pipes

Polypropylene Random Copolymer (PPR) pipes are known for their superior material characteristics, which make them highly suitable for a wide range of piping applications—from domestic plumbing to complex industrial systems. The unique combination of mechanical, thermal, and chemical properties allows PPR pipes to outperform many traditional and modern piping materials. Below is an in-depth overview of the key properties that define the performance and reliability of PPR pipes.

2.1 Material Composition and Structure

PPR pipes are manufactured from polypropylene random copolymer—a high-grade thermoplastic that is created through the polymerization of propylene monomers with ethylene. This molecular arrangement leads to a random distribution of ethylene molecules within the polypropylene chain, which enhances flexibility, impact resistance, and thermal stability.

The resulting structure gives PPR an ideal balance between rigidity and toughness. It ensures that the pipes can handle both internal pressure and external mechanical stress without cracking or deforming. Additionally, the smooth internal surface of PPR pipes helps reduce friction losses, ensuring efficient fluid flow with minimal pressure drop.

2.2 Temperature Resistance: Hot and Cold Water Performance

One of the standout features of PPR pipes is their ability to withstand both high and low temperatures, making them suitable for hot and cold water supply systems:

Maximum continuous working temperature: ~70°C (158°F)

Short-term exposure temperature: Up to 95°C (203°F)

Minimum temperature tolerance: Down to -20°C (-4°F), with proper insulation

These temperature resistance capabilities make PPR ideal for residential hot water systems, central heating applications, and even solar water heating systems. The material maintains its shape and strength across a wide thermal range, unlike some plastics that may become brittle or deform under heat.

2.3 Pressure Rating and Mechanical Strength

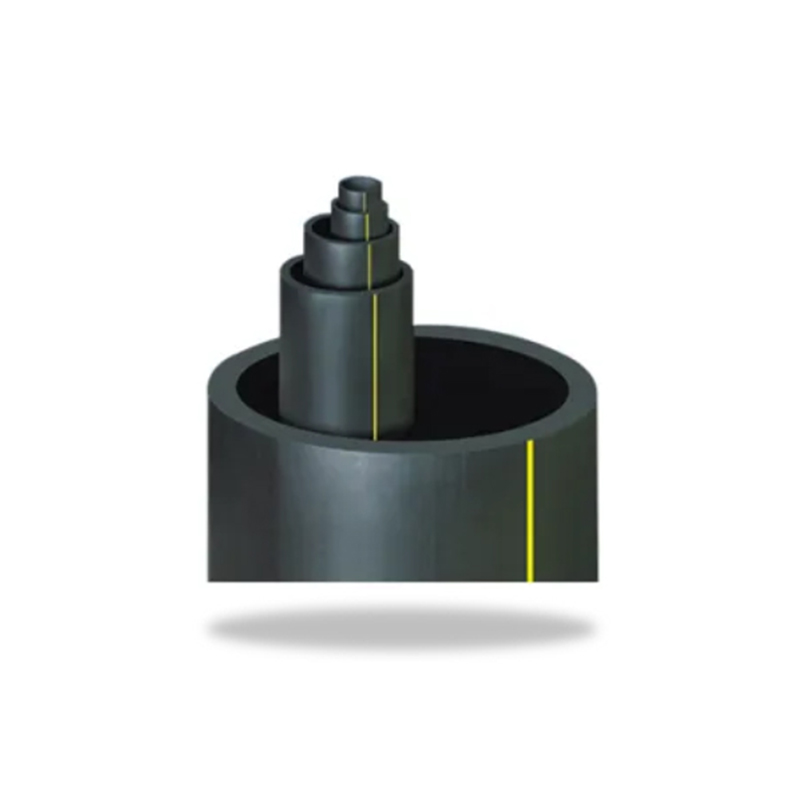

PPR pipes are available in various pressure classes (PN10, PN16, PN20, and PN25), indicating their ability to handle different pressure loads at specified temperatures. The mechanical strength of the pipe is determined by its wall thickness and diameter, and the material's high modulus of elasticity gives it excellent resistance to internal pressure.

For example:

PN10: Suitable for cold water distribution at moderate pressure

PN16/PN20: Commonly used for hot and cold water supply in buildings

PN25: Used for high-pressure hot water systems and heating circuits

PPR pipes exhibit excellent long-term hydrostatic strength, meaning they can handle continuous pressure over decades without significant material fatigue or rupture.

2.4 Chemical Resistance to Various Substances

Another major advantage of PPR is its chemical resistance. PPR is inert to a wide range of chemical agents, including most acids, bases, and salts. This makes it particularly suitable for industrial applications where aggressive substances are transported, such as:

Chemical effluents in factories

Acidic or alkaline process fluids

Water treatment plants

Laboratories and medical facilities

However, PPR may not be suitable for strong oxidizing agents like concentrated nitric acid or chlorine-rich solutions under high temperatures. Compatibility checks should always be performed for aggressive chemicals.

2.5 Thermal Insulation Properties

PPR has low thermal conductivity—approximately 0.24 W/m·K—which provides it with excellent thermal insulation properties compared to metal pipes. This property is especially beneficial in heating and hot water applications because it helps:

Minimize heat loss over long pipe runs

Reduce energy consumption in heating systems

Maintain consistent water temperatures

Eliminate the need for additional insulation in many scenarios

In contrast, materials like copper or steel have much higher thermal conductivity, leading to significant energy losses unless insulated separately.

2.6 Acoustic Properties (Noise Reduction)

PPR pipes contribute positively to the acoustic comfort of buildings. The density and elasticity of the material help absorb vibrations and dampen noise transmission caused by fluid flow or water hammer effects. This is particularly valuable in residential and commercial buildings where noise from piping systems can be a concern.

In comparison to metallic pipes, which often transmit noise, PPR pipes offer quieter operation, especially in vertical installations like risers in apartment buildings or office towers.

2.7 Environmental Impact and Recyclability

Sustainability is an increasingly important consideration in construction and manufacturing. PPR performs well in this regard due to its:

Recyclability: 100% recyclable with minimal environmental impact during disposal.

Non-toxic composition: PPR does not release harmful chemicals or pollutants into water or the environment.

Energy-efficient production: Manufacturing PPR requires less energy than metals and other plastics like PVC.

Low carbon footprint: Due to its long service life and low maintenance requirements, PPR systems reduce resource consumption over time.

Additionally, PPR pipes contribute to green building certifications (such as LEED) and align with environmentally responsible construction practices.

2.8 Resistance to Scaling and Biofilm Formation

The smooth internal surface of PPR pipes not only reduces pressure loss but also helps in resisting the formation of scale, biofilms, and other deposits. This is particularly advantageous for:

Potable water supply: Maintains water purity and hygiene

Heating systems: Prevents clogging and efficiency loss

Medical and food industries: Ensures sterility and cleanliness

Unlike metal pipes, which are prone to rust and scaling, PPR maintains its integrity without introducing foreign particles or contaminants into the system.

2.9 UV Resistance (With Limitations)

While PPR pipes are excellent for indoor use, prolonged exposure to ultraviolet (UV) radiation can degrade the material, causing discoloration and embrittlement over time. For outdoor installations or areas exposed to sunlight, UV-protected versions of PPR pipes or external shielding (such as insulation or conduit) should be used to maintain performance and longevity.

Manufacturers may offer UV-stabilized variants or recommend painting or wrapping exposed pipes with UV-resistant materials.

2.10 Low Thermal Expansion

Compared to metals, PPR has a higher coefficient of thermal expansion (approximately 0.15 mm/m·K). However, this can be managed effectively with proper pipe supports, installation techniques, and compensators such as expansion loops. When correctly installed, thermal expansion does not negatively impact the functionality or appearance of the piping system.

Design considerations such as:

Allowing space for expansion

Anchoring and guiding supports

Using flexible installation paths

…help control movement and prevent stress on joints.

Summary

PPR pipes offer a versatile and high-performance solution for modern piping systems. Their key properties include:

Excellent chemical and temperature resistance

High mechanical strength and pressure capacity

Outstanding thermal and acoustic insulation

Long-term durability and environmental sustainability

Resistance to corrosion, scaling, and biofilm formation

These features make PPR a preferred material in a wide range of sectors, including residential plumbing, commercial HVAC, industrial process piping, and more.

3. Advantages of Using PPR Pipes

Polypropylene Random Copolymer (PPR) pipes have become a preferred choice in modern plumbing, HVAC, and industrial systems due to their unique combination of mechanical, thermal, chemical, and economic benefits. The advantages of PPR pipes extend beyond durability and ease of installation—they also support health and safety standards, sustainability goals, and long-term cost savings. Below is a comprehensive exploration of the major advantages that PPR piping systems offer.

3.1 Longevity and Durability

One of the most compelling reasons for choosing PPR pipes is their exceptional lifespan. Under normal operating conditions, PPR pipes can last 50 years or more without significant degradation. Their molecular structure and resistance to corrosion, scaling, and cracking allow them to maintain integrity over decades, even in demanding environments.

Unlike metal pipes, which may corrode, rust, or pit over time, PPR does not suffer from oxidation or electrochemical wear. This makes it a reliable long-term investment, particularly in residential buildings, hospitals, hotels, and infrastructure projects where piping systems are expected to operate maintenance-free for generations.

3.2 Corrosion Resistance

Corrosion is one of the most common causes of failure in traditional piping systems, especially in areas with aggressive water chemistry or corrosive environments. PPR pipes are completely resistant to:

Electrochemical reactions (such as galvanic corrosion)

Acidic or alkaline water

Mineral scaling or deposits

Moisture-induced surface degradation

As a result, they are suitable for both drinking water and chemical transport applications. Unlike metal systems, there’s no need for internal coatings, linings, or inhibitors to protect the pipe interior, reducing complexity and cost.

3.3 Hygienic Properties for Potable Water

Ensuring the safety of drinking water is critical. PPR is a non-toxic, food-grade material that does not release any harmful substances into the water supply. It is compliant with international standards for potable water systems (such as ISO 15874, ASTM F2389, and others), making it ideal for municipal water distribution and household plumbing.

Additionally, PPR’s smooth inner surface inhibits bacterial growth, biofilm formation, or scaling that might compromise water purity. This hygienic performance makes it the material of choice for:

Domestic water supply networks

Hospitals and healthcare facilities

Food and beverage processing plants

Pharmaceutical water systems

3.4 Lightweight and Easy to Handle

PPR pipes are significantly lighter than traditional metal pipes, which translates into easier transportation, handling, and installation. For example, a meter of PPR pipe weighs a fraction of the equivalent-length steel or copper pipe. This results in several advantages:

Reduced labor costs: Smaller installation teams and no need for heavy equipment

Faster installation times: Especially in multi-story buildings or tight spaces

Lower transportation expenses: Easier logistics and reduced fuel usage

Their lightweight nature also makes them safer to handle, reducing the risk of workplace injuries and simplifying overhead or ceiling-mounted installations.

3.5 Heat Preservation

With a low thermal conductivity of around 0.24 W/m·K, PPR pipes provide excellent insulation and heat retention. This characteristic is particularly useful in heating systems and hot water distribution, where maintaining temperature is crucial for energy efficiency and user comfort.

Benefits include:

Reduced heat loss over long pipe runs

Lower energy bills for building owners

Stable water temperature at outlets

Improved performance of underfloor heating systems

In many cases, PPR pipes eliminate the need for additional insulation, further reducing installation time and materials cost.

3.6 Cost-Effectiveness

PPR offers outstanding value over its life cycle. While the initial material cost may be comparable to other piping materials (such as CPVC or PEX), the total cost of ownership is significantly lower due to:

Minimal maintenance requirements

Long service life

Low installation labor costs

Reduced risk of leaks or system failure

No need for corrosion protection or painting

In large-scale projects, the cumulative savings can be substantial. Developers, contractors, and facility managers often favor PPR due to its reliability, low upkeep, and minimal downtime once installed.

3.7 Excellent Joint Integrity via Heat Fusion

PPR pipe systems are assembled using thermofusion (heat fusion) welding, a method that permanently bonds the pipe and fitting at the molecular level. When correctly performed, the joint becomes as strong as the pipe itself, eliminating weak points and reducing the chance of future leaks.

Key advantages of heat fusion:

No adhesives or solvents required (which may be toxic or degrade over time)

No mechanical fittings prone to loosening

High-pressure and high-temperature performance

Resistant to vibration or thermal expansion stress

This jointing method is a major reason why PPR systems outperform many alternative plastics and metals in demanding applications.

3.8 Flexibility and Impact Resistance

Thanks to its molecular structure and elastic modulus, PPR has a moderate degree of flexibility, allowing it to absorb shocks and mechanical impacts without cracking. This property is beneficial in:

Seismic areas where vibration or ground movement can stress rigid materials

Cold environments where impact resistance at low temperatures is essential

Industrial settings where accidental bumps or drops might occur

While not as flexible as PEX, PPR still offers enough ductility to be shaped during installation without breaking, particularly when heat is applied.

3.9 Environmentally Friendly

As environmental sustainability becomes a core concern in modern construction, PPR stands out as a green building material:

100% recyclable at the end of its life cycle

No harmful emissions during use or welding

Energy-efficient manufacturing process

Free of BPA, chlorine, or heavy metals

These eco-friendly characteristics help PPR comply with environmental standards like LEED (Leadership in Energy and Environmental Design) and support the development of low-impact, sustainable infrastructure.

3.10 Compatibility with Various Systems

PPR pipes are compatible with a wide range of systems and can be connected to different materials using transition fittings, such as:

Metal-to-PPR connectors for copper or steel systems

Threaded fittings for valves and equipment

Composite fittings for hybrid systems

This makes PPR an ideal solution for both new construction and renovation projects, where it may need to interface with existing metal or PVC networks. Its adaptability reduces the need to replace entire systems and allows partial upgrades with minimal disruption.

3.11 Reduced Noise Levels

In multi-unit buildings such as hotels or apartment complexes, water noise through pipes can be a nuisance. PPR pipes naturally dampen water flow noise due to their thick walls and thermoplastic nature. Compared to metal pipes, which amplify sound, PPR helps maintain a quiet indoor environment.

3.12 Low Thermal Expansion Stress (When Properly Installed)

Though PPR has a higher thermal expansion coefficient than metals, it handles temperature changes well when properly supported and installed. Expansion loops, flexible routing, and correct anchoring allow for system movement without placing undue stress on joints or walls.

This allows PPR to be used safely in:

Hot water circulation lines

Radiant floor heating

Solar water heating

Proper planning ensures long-term performance without warping or structural strain.

Summary

PPR pipes deliver a wide range of advantages that make them superior to many other piping materials in modern construction and industrial applications. Their outstanding durability, chemical and corrosion resistance, hygienic performance, ease of installation, and overall cost-effectiveness make them the material of choice for numerous professionals across plumbing, HVAC, agriculture, and industrial sectors.

Key advantages include:

Long service life (50 years)

Resistance to corrosion and scaling

Safe for drinking water

Lightweight and easy to handle

Excellent heat and acoustic insulation

Strong, leak-proof joints via heat fusion

Environmental sustainability

Low maintenance and low lifetime costs

As technology continues to improve, the demand for reliable, efficient, and sustainable piping systems will grow—and PPR is well-positioned to meet that demand.

4. Disadvantages of Using PPR Pipes

While PPR (Polypropylene Random Copolymer) pipes offer numerous advantages that make them a popular choice in modern piping systems, they are not without limitations. Like any material, PPR has specific drawbacks that must be understood and addressed to ensure proper application and long-term performance. This section outlines the most significant disadvantages of PPR pipes, along with context and considerations for mitigating these issues.

4.1 Temperature Limitations Compared to Other Materials

Although PPR pipes perform well in hot and cold water systems, their upper temperature limit is lower than some alternative materials, especially metals or high-performance plastics like CPVC or stainless steel.

Maximum continuous operating temperature: ~70°C (158°F)

Maximum short-term exposure: 95°C (203°F)

Deformation risk: Prolonged exposure to temperatures near or above these limits can lead to softening, deformation, or even pipe failure under pressure.

In contrast, materials like CPVC can sustain continuous temperatures of 90°C or more, while metal pipes can operate well beyond 100°C. For high-temperature industrial processes or heating systems requiring sustained temperatures above 70°C, PPR may not be the most suitable choice.

Mitigation: Limit use of PPR to systems that stay within the recommended temperature range. For mixed systems, install metal or CPVC piping in high-heat sections and connect to PPR downstream.

4.2 Combustibility

PPR, like most thermoplastics, is combustible. While it does not ignite as easily as some plastics and may self-extinguish in the absence of flame, it can still contribute to fire spread when exposed to open flame or high temperatures. During combustion, it may emit smoke and toxic gases.

Comparison with other materials:

Copper and steel: Non-combustible and ideal for fire-prone areas.

CPVC: Better flame resistance, often with UL certifications for fire suppression systems.

Use limitations:

Not suitable for installation near open flame or in areas with high fire risk.

Building codes may restrict the use of PPR in certain environments (e.g., escape routes, mechanical rooms).

Mitigation:

Use protective conduit or insulation to shield PPR from heat.

Avoid placing PPR pipes near potential ignition sources.

Consider fire-resistant alternatives in areas with strict fire safety requirements.

4.3 Expansion Rate

PPR exhibits a relatively high coefficient of thermal expansion, especially when compared to materials like copper or steel. The expansion coefficient is approximately 0.15 mm/m·K, meaning the pipe length increases noticeably with temperature rise.

For example:

A 10-meter PPR pipe experiencing a 50°C rise will expand by ~7.5 mm.

In hot water lines or heating systems, this can cause visible pipe movement or stress at joints if not managed properly.

Potential problems:

Pipe buckling or sagging

Cracked walls or mounting brackets

Stress at fittings and joints leading to leaks

Mitigation:

Use of expansion loops, flexible connections, and sliding pipe supports

Installation of anchors and guides according to technical guidelines

Proper spacing of pipe clamps to accommodate movement

When well-designed, thermal expansion is manageable and will not negatively affect system integrity.

4.4 UV Resistance

One of the most critical weaknesses of PPR is its sensitivity to ultraviolet (UV) radiation. Prolonged exposure to sunlight or other UV sources can degrade the pipe’s outer surface, leading to:

Discoloration and chalking

Surface embrittlement

Reduction in mechanical strength

Cracking or premature failure

PPR is best suited for indoor use or buried installations. For outdoor applications, PPR should not be left unprotected unless it has been specially modified for UV resistance.

Mitigation:

Apply UV-resistant coatings or paints

Use black UV-stabilized PPR variants (offered by some manufacturers)

Encase exposed pipes in conduit or insulation

Avoid rooftop or open-air installations without proper protection

Where long-term exposure is unavoidable, alternative materials like HDPE or UV-rated PVC may be more appropriate.

4.5 Limited Flexibility Compared to PEX

Although PPR has better flexibility than rigid metals, it is more rigid than PEX (cross-linked polyethylene). This can make installation slightly more complex in tight or irregular spaces.

Challenges include:

Requires fittings for directional changes instead of bending

Larger turning radii than PEX

Harder to work with in retrofit applications or confined areas

Mitigation:

Plan piping routes carefully to reduce excessive fittings

Preheat and bend where appropriate

Choose PEX for highly flexible or serpentine layouts (e.g., retrofitting small bathrooms)

4.6 Requires Specialized Fusion Equipment

The heat fusion method used to join PPR pipes provides strong, leak-proof joints, but it also requires specialized tools and trained personnel.

Challenges:

Initial equipment investment

Training requirements for installers

Slower setup compared to mechanical fittings

This may pose difficulties for small-scale installations or repairs where specialized tools are not available. In emergency situations, traditional threaded or mechanical fittings (used with metal or CPVC) may offer faster results.

Mitigation:

For large projects, include fusion tools in project planning

Train staff in proper fusion techniques

Use hybrid connections (e.g., transition fittings) where appropriate

4.7 Brittle at Extremely Low Temperatures

While PPR performs well down to about -20°C (-4°F), it becomes increasingly brittle at sub-zero temperatures, especially during handling or installation.

Pipes may crack under impact during cold weather transport or fitting

Installation in unheated environments must be carefully managed

In contrast, materials like HDPE or specially formulated PEX can offer better performance in freezing conditions.

Mitigation:

Store and handle PPR pipes at recommended temperatures

Warm pipes before cutting or welding in cold climates

Insulate pipes to avoid freezing water inside the system

4.8 Pressure Resistance Drops at High Temperatures

PPR pipes are pressure-rated based on temperature. As temperature increases, the pressure resistance of the material decreases.

For example:

A PN20 pipe (rated for 20 bar at 20°C) may only handle 6-8 bar at 70°C.

If these limits are not considered in system design, the pipe may deform or rupture under thermal and pressure stress combined.

Mitigation:

Use correct pressure class (PN10, PN16, PN20, PN25) based on system temperature and pressure

Avoid oversizing or undersizing pipes

Consult manufacturer pressure-temperature charts

4.9 Environmental Stress Cracking (Rare but Possible)

In rare cases, PPR can be susceptible to environmental stress cracking, especially when exposed to certain chemicals in combination with mechanical stress or poor installation practices.

Factors that contribute to stress cracking:

Over-tightened fittings

Surface damage or scratches

Chemical exposure from cleaning agents or fluids

Improper support or pipe misalignment

Mitigation:

Follow manufacturer guidelines for bending radius, installation supports, and torque

Avoid chemical exposure unless the material is certified for it

Inspect for surface damage before and after installation

Summary

While PPR pipes offer many impressive benefits, they are not perfect. Understanding their limitations is critical to ensuring proper selection, installation, and system longevity. By anticipating potential challenges—such as temperature sensitivity, UV degradation, or expansion issues—contractors and designers can implement effective strategies to mitigate risks.

5. Common Applications of PPR Pipes

Polypropylene Random Copolymer (PPR) pipes have become a popular choice in a wide range of piping applications due to their unique blend of mechanical durability, chemical resistance, hygienic properties, and ease of installation. As the construction, manufacturing, and infrastructure sectors evolve, the need for reliable and sustainable piping systems becomes more critical—and PPR pipes are often at the center of these systems.

This section explores the most common and impactful applications of PPR pipes across various sectors including residential, commercial, industrial, and agricultural settings. Each application leverages specific benefits of PPR, making it a versatile and dependable piping solution.

5.1 Plumbing Systems (Hot and Cold Water Distribution)

The most widespread use of PPR pipes is in plumbing systems for domestic and commercial buildings, where they serve both hot and cold water distribution. Due to their excellent resistance to heat, pressure, and corrosion, PPR pipes are now considered a superior alternative to traditional metal pipes such as copper or galvanized steel.

Key advantages in plumbing:

No corrosion or scaling: Ensures long-term clean water supply

Hygienic surface: Smooth inner walls inhibit bacterial growth

High temperature tolerance: Supports water heating systems up to 70°C continuously

Silent operation: Reduces noise compared to metal pipes

PPR plumbing systems are commonly found in:

Residential houses and apartment buildings

Hotels and resorts

Hospitals and clinics

Educational institutions

Public washrooms and restrooms

Because of their non-toxic nature and ability to preserve water quality, PPR pipes are frequently used for potable water systems, both for drinking and bathing purposes.

5.2 Heating Systems (Radiator Connections, Underfloor Heating)

In many regions with cold climates, PPR pipes are extensively used in heating systems, especially those involving warm water circulation. Their ability to handle elevated temperatures and pressure makes them ideal for delivering heated water to radiators and underfloor heating systems.

Applications include:

Radiator connections: Linking boilers or heat pumps to room radiators

Hydronic underfloor heating: Network of PPR pipes beneath flooring to radiate heat evenly

Hot water loops: Circulation systems that maintain water temperature over long distances

PPR pipes are well-suited for heating applications because:

They offer low thermal conductivity, which reduces heat loss

They are chemically resistant to common antifreeze and heating fluids

The heat fusion welding process ensures leak-proof connections, crucial in closed-loop systems

In underfloor heating, PPR’s flexibility, durability, and longevity are essential for installations embedded in concrete slabs or tiled flooring where future maintenance is difficult.

5.3 Industrial Applications (Chemical Transport, Compressed Air)

PPR pipes are also gaining significant traction in industrial environments, where their resistance to a broad spectrum of chemicals and excellent mechanical properties provide a safe and cost-effective solution for fluid transport.

Common industrial applications:

Chemical transportation systems: Especially in pharmaceutical, textile, and chemical industries

Compressed air lines: Used in workshops, factories, and automation systems

Cooling water systems: For industrial equipment and machinery

Deionized and purified water distribution

PPR pipes perform well in these settings because:

They resist acids, alkalis, and many solvents

They are non-reactive, preventing contamination

They are non-conductive, minimizing risk in electro-sensitive environments

They are durable under pressure, making them reliable for compressed air systems

Additionally, because PPR pipes are lightweight and easy to install using fusion welding, they reduce downtime and labor costs during industrial maintenance or system upgrades.

5.4 Agriculture (Irrigation Systems)

In the agricultural sector, the need for reliable and weather-resistant piping systems is vital for efficient water use and productivity. PPR pipes are increasingly used in agricultural irrigation and greenhouse water management due to their resistance to chemical fertilizers and extreme outdoor conditions.

Uses in agriculture:

Drip irrigation systems

Sprinkler irrigation

Mainline water distribution for farms

Greenhouse misting and cooling systems

Fertilizer mixing and transport lines

Why PPR suits agriculture:

Resistant to UV degradation when properly coated or buried

Handles fertilizer mixtures and water containing dissolved minerals

Maintains performance over long distances due to low friction loss

Affordable and durable compared to metal pipes for outdoor systems

Farmers and agricultural engineers appreciate the long service life of PPR pipes (up to 50 years) and their compatibility with automation systems and sensors used in modern irrigation control.

5.5 Other Specialized Uses

Beyond the core sectors mentioned, PPR pipes have found specialized use cases where their material characteristics offer unique benefits. These include sectors such as telecommunications, food processing, shipbuilding, and even in renewable energy systems.

Some notable applications:

Food and Beverage Industry:

Transport of clean water, juices, or other fluids in food production

Used in sanitary installations in processing plants

Preferred for CIP (Clean-In-Place) systems because of their hygiene and chemical resistance

Shipbuilding and Marine Applications:

PPR is used in potable water lines, cooling systems, and sanitation networks on ships

Offers corrosion resistance to saltwater and marine conditions

Lightweight nature helps reduce vessel weight compared to metal piping

Renewable Energy Systems:

In solar thermal water heaters, PPR pipes connect collector panels to storage tanks

Used in geothermal systems for circulating low-temperature fluids

HVAC Systems (Heating, Ventilation, Air Conditioning):

PPR is utilized for chilled water lines, condensate drainage, and coolant distribution

Telecommunications Infrastructure:

PPR pipes act as protective conduits for underground fiber optic and electrical cables

These niche uses demonstrate the adaptability of PPR pipes beyond just water distribution, showing their increasing value across diverse engineering fields.

Why PPR is Preferred in Modern Infrastructure Projects

In large-scale infrastructure projects, especially in developing regions or eco-sensitive areas, PPR pipes have become a go-to solution for long-term sustainability. This preference stems from several systemic advantages:

Quick installation and low labor requirements

Environmental safety due to lack of heavy metals or toxic substances

Long service life, reducing maintenance needs

Low energy consumption during production compared to metal piping

As nations invest in upgrading old water systems, especially in urban planning and rural development, PPR offers a cost-efficient, future-ready material that aligns with modern construction standards.

Limitations in Certain Applications

Despite its wide usage, PPR does have limitations in specific applications:

Not suitable for fuel or gas pipelines (flammability and permeability issues)

Not ideal for exposed rooftop plumbing unless UV-protected

Limited flexibility in dynamic applications like seismic areas unless properly anchored

In such scenarios, alternatives such as HDPE, PVC-U, CPVC, or metal may be better suited, depending on the exact requirements.

From residential water systems to high-performance industrial applications, the versatility of PPR pipes is well-proven. Their growing adoption is not just based on cost or convenience but also on performance reliability, environmental compatibility, and system longevity. Whether carrying potable water through a modern apartment complex, maintaining precise temperatures in a heating network, or supporting irrigation on a rural farm, PPR pipes consistently deliver performance.

The future of infrastructure will continue to favor materials that offer sustainability, durability, and safety. PPR stands out in this respect, with applications that continue to evolve as technology and design practices advance.

Polypropylene Random Copolymer (PPR) pipes have become a prominent choice in modern piping systems due to their excellent balance of physical, chemical, and environmental properties. Manufactured from a thermoplastic polymer known for its durability and heat resistance, PPR pipes are widely used in residential, commercial, industrial, and agricultural applications. They offer significant advantages such as corrosion resistance, long lifespan, hygienic qualities ideal for potable water, and ease of installation thanks to their lightweight nature and heat fusion joining technique. Their thermal insulation properties reduce heat loss, making them suitable for hot and cold water distribution as well as heating systems like radiator connections and underfloor heating. PPR pipes also demonstrate strong resistance to a variety of chemicals and physical stresses, contributing to their reliability in demanding environments.

Despite these benefits, PPR pipes have certain limitations. Their operating temperature range is lower compared to some alternatives like CPVC or metal pipes, restricting use in very high-temperature applications. They are combustible, vulnerable to UV degradation without protective measures, and exhibit a relatively high coefficient of thermal expansion, which requires careful installation to manage pipe movement. Additionally, PPR pipes need specialized fusion equipment for reliable joints and can become brittle at very low temperatures. These factors should be considered during system design and material selection.

The broad applicability of PPR pipes encompasses plumbing systems for hot and cold water, heating installations, industrial fluid and compressed air transport, and agricultural irrigation systems. Their hygienic, corrosion-free, and non-toxic nature makes them especially popular in potable water supply networks and food processing industries. Industrial uses benefit from their chemical resistance and durability, while agricultural applications exploit their resistance to fertilizers and environmental conditions. Specialized uses also include marine water systems, renewable energy installations, and protective conduits for telecommunications.

Standardization of PPR pipes includes a variety of sizes, pressure ratings, and fitting types, supporting versatility across projects. Proper installation procedures involving heat fusion ensure leak-proof, durable joints, while standards and certifications guarantee product quality and safety compliance.

In conclusion, PPR pipes offer an effective, economical, and environmentally friendly piping solution across many sectors. Their balance of durability, ease of use, and safety positions them as a future-ready technology for infrastructure development worldwide. While recognizing their limitations, when applied correctly, PPR pipes provide a reliable and sustainable option for modern fluid distribution and piping needs.

简体中文

简体中文